Differences between HPMC and MHEC in dry-mix applications

1. Chemical structure differences

HPMC:Contains hydroxypropyl (-O-CH2-CHOH-CH3) and methyl (-O-CH3) substituents.

MHEC: Contains methyl (-O-CH3) and hydroxyethyl (-O-CH2-CH2-OH) substituents.

Impact: Hydroxypropyl is slightly more hydrophobic than hydroxyethyl, resulting in different solubility and temperature response.

2. Solubility and gelation temperature

HPMC:Cold water dissolves more slowly and may take longer to disperse (especially in low viscosity products).

Thermal gelation temperature is higher (usually 60-90℃), more stable at high temperatures, suitable for hot environments.

MHEC:Faster dissolution and better dispersibility.

Thermal gelation temperature is lower (about 40-60℃), easy to gel at high temperatures, which may limit its use in hot climates.

3. Water retention capacity

HPMC: Stronger water retention, longer mortar open time, reduced water evaporation, suitable for dry environment or thick layer construction.

MHEC: Slightly weaker water retention, but may be more suitable for occasions that require moderate water release (such as rapid hardening requirements).

4. Viscosity and rheology

HPMC: Wide viscosity range (low to ultra-high viscosity), strong adjustability, providing better anti-sagging (suitable for vertical surface construction).

MHEC: Smoother rheology, better construction feel, may improve leveling efficiency.

5. Temperature stability

HPMC: Stable performance at high temperature (high gel temperature), suitable for hot areas or summer construction.

MHEC: Better performance in low temperature environment, high temperature easy gel may affect construction.

6. Compatibility with cement

HPMC: Excellent stability in a strong alkaline environment, good compatibility with most cements.

MHEC: May have better synergistic effects with certain additives (such as latex powder), but specific formula verification is required.

7. Cost and market application

HPMC: It is widely used and cost-effective, and is the mainstream choice for dry-mixed mortar.

MHEC: The price is usually higher, but it may perform better in certain areas (such as self-leveling mortar).

8. Typical application scenarios

HPMC:

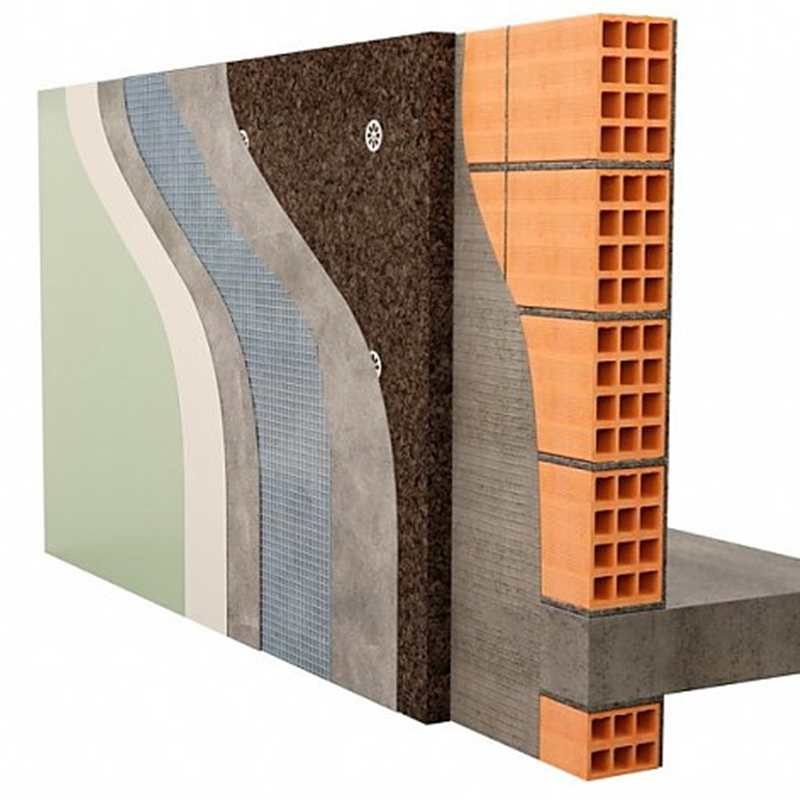

Exterior wall plastering, tile adhesive (requires high water retention and anti-sagging).

High temperature environment construction (such as floor mortar).

MHEC:

Self-leveling mortar (quick dissolution, good leveling).

Indoor putty (high construction smoothness requirements).

Name:Erica Wei

E-mail:erica@mailose.com