Cellulose ether is polymer compound that have ether structure made from cellulose. Currently, the two kinds of most common raw materials are refined cotton and wood pulp. China is one of the most important cotton planting country all over the world, So, most Chinese cellulose ether producer choice to use refined cotton as their raw material in production.In the past 5 years, the global demand of cellulose was keeping increasing in many different using area including construction mortar, food, pharmaceutical, texile, adhesives, paint and costings, personal care and oil drilling etc.Cellulose ether includes many different kinds of products, for example, methyl cellulose(MC), Hydroxypropyl methyl cellulose(hpmc), hydroxyethyl methyl cellulose(HEMC), Ethyl cellulose(EC), Hydroxyethyl cellulose(HEC) and dodium carboxymetnhyl cellulose(Na-cmc) etc.

1. Classifications of cellulose ether

According to the different solubility, cellulose ether could divide into water-soluble and organic solvents soluble. According to the classification of substituents, it can be divided into ionic and non-ionic cellulose ether.

Classifications | Cellulose ether | Water-soluble | Short name |

Non-ionic cellulose ether | Hydroxypropyl methyl cellulose | √ | HPMC |

Methyl cellulose | √ | MC |

Ethyl cellulose | × | EC |

Hydroxyethyl cellulose | √ | HEC |

Hydroxypropyl cellulose | √ | HPC |

Methyl hydroxyethyl cellulose | √ | MHEC |

Ionic cellulose ether | Sodium carboxymethyl cellulose | √ | Na-CMC |

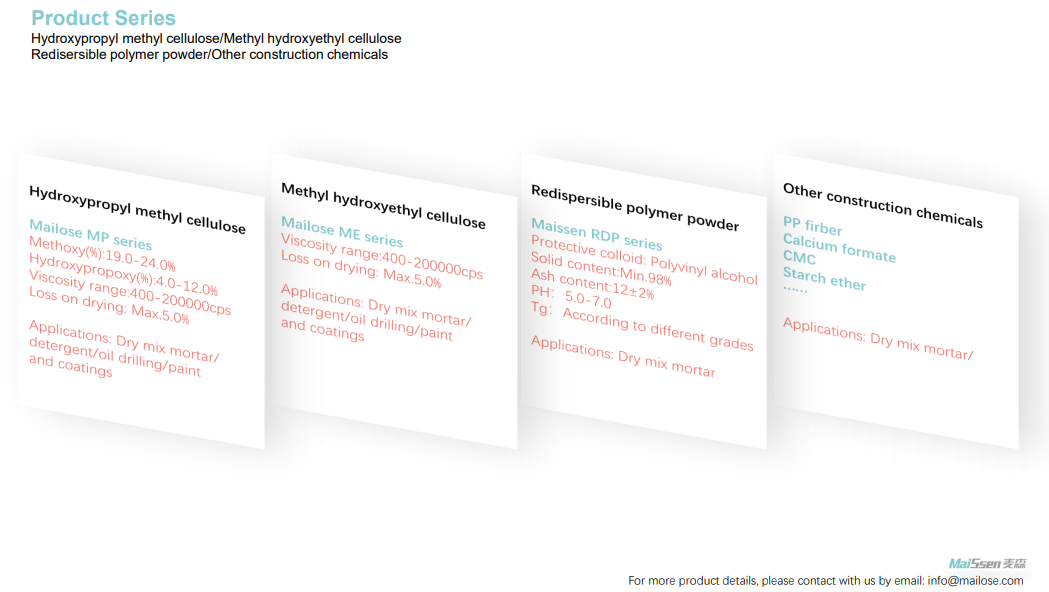

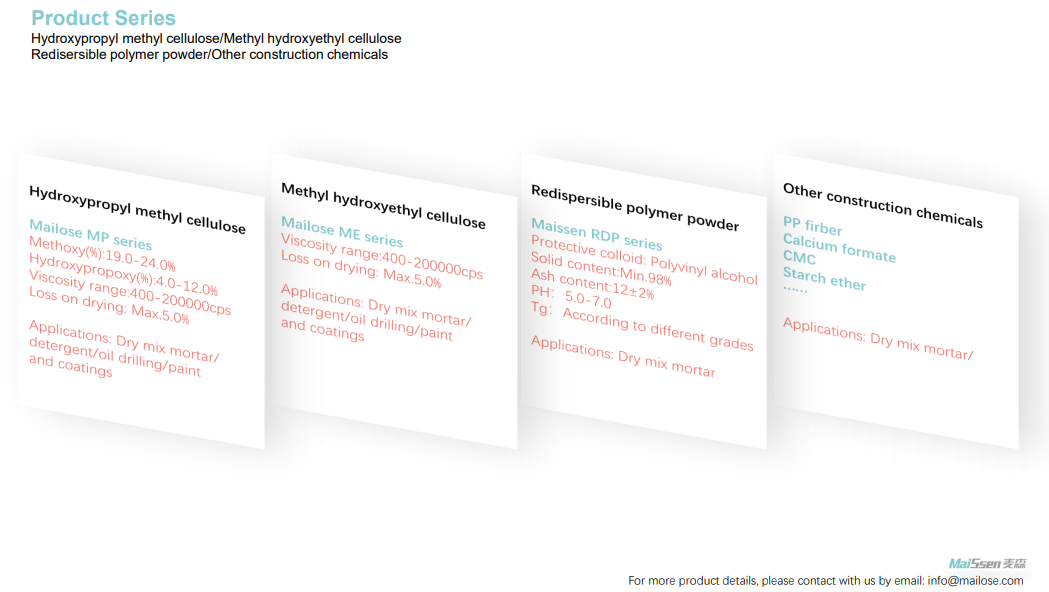

Jinan maissen new material co.,ltd is the non-ionic cellulose producer in China. Main cellulose ether products include HPMC (hydroxypropyl methyl cellulose) and HEMC (hydroxyethyl methyl cellulose) which are two kinds of no-ionic cellulose ether widely used in construction mortar and detergent applications.

HPMC (hydroxypropyl methyl cellulose) and HEMC(hydroxyethyl methyl cellulose) are most popular two kinds in dry mix mortar industry because of their good stability and good water retention function. They can also improve the cohesion, viscosity and workability of the wet mortar. These two products are accepted by dry mix mortar producers all over the world.

2. The solubility of cellulose ether

Cellulose ether is a kind of basic additives for drymix mortar industry. The dosage is only 0.1%-1%, but the dry mix mortar performance is effected by it significantly. Cellulose ether could improve the consistency and water retention of the dry mix mortar products. it is depends on cellulose ether's water-solubility. The main index effected on the solubility of cellulose ether includes: string speed, particle size and soluble time etc.

For example, for a HPMC with viscosity 50 mPa.s, it need 10 min to reach the highest viscosity point, but for HPMC with the viscosity 20000 mPa.s, it need 40 minutes to reach the highest viscosity point. We an say that the cellulose ether with higher viscosity, the longer time needed to reach the highest viscosity.

Meanwhile, the string speed also effect on the solubility of cellulose ether also. For example, HPMC with 20000mPas viscosity need 40 min. to reach the viscosity highest point under high speed string. But under low speed string, it will need 150 minutes.

3. The particle size of cellulose ether

The particle size of cellulose will be also effected on the viscosity increasing in solution. Jinan maissen new material co.,ltd could provide HPMC and HEMC with different particle size according to customers' requirements. HPMC with different particle size won't effect on the final viscosity of the solution , but it make contributions on the viscosity increasing speed. Particle size is smaller, the viscosity will increase faster.

4. The viscosity of cellulose ether

The viscosity of cellulose ether is one of the most important index for their application performance. We need to choose the right viscosity according to the different applications.

For the water-soluble cellulose ether-HPMC,MHEC,MC etc, it need to solve in water and test the viscosity by viscometer. Currently there are many different viscosity test methods depends on different producers all over the world. Common viscometer includes: Roto, NDJ, Brookfield, Hoppler, Ubelode etc.

(1) The viscosity test result will be different according to different test method.

(2) Test by same viscometer with different concentration of the solution, the result will be different. For example,1% solution and 2% solution tested by Brookfield, the result is much different.

(3) The temperature have influence on the viscosity test result

Below table could help us to understand the difference.

NDJ-1 2% solution, 20℃ | Brookfield

RV 2% solution,20℃ | Hoppler | Roto |

60000 | 30000 | 60000 | 30000 |

75000 | 35000 | 75000 | 35000 |

100000 | 40000 | 100000 | 40000 |

150000 | 60000 | 150000 | 60000 |

200000 | 70000+ | 200000 | 70000+ |

P.S.: the viscosity range is approximately.

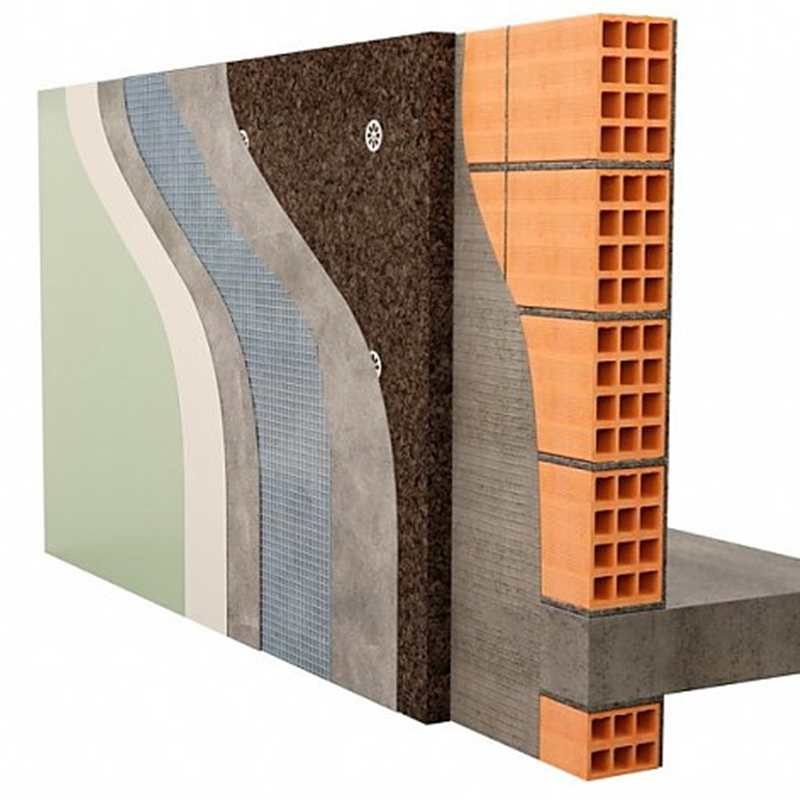

5. Cellulose ether in dry mix mortar industry

In dry mix mortar industry, HEMC and HPMC are most popular two kinds of cellulose. They can keep stability in cement or gypsum product system. It is used as an basic additive in the formulation. Provide good water retention, cohesion and workability. Meanwhile, make sure all other additives in the formulation to reach the best performance.

To choose different specifications in the different kinds of dry mix mortar products. The recommendation sheet below may be helpful:

Block laying adhesive | Mailose MP 150K/ME150K Mailose MP40K/ME40K |

Cement or gypsum based plaster | Mailose MP100K/ME100K Mailose MP60K/ME60K |

Cement or gypsum based one coat | Mailose MP60K/ME60K Mailose MP40K/MP40K |

Tile adhesive | Mailose MP150K/ME150K Mailose MP200K/ME200K Mailose MP150KO Mailose MP200KO |

Joint compound | Mailose MP40K/ME40 |

Gypsum spray plaster | Mailose MP75K/ME75K Mailose MP75KM |

Skim coat/wall putty | Mailose MP100K/ME100K |

EIFS adhesive mortar | Mailose MP150K/ME150K Mailose MP100K/ME100K |

EIFS surface mortar | Mailose MP100K/ME100K Mailose 60K/ME60K |

Self-leveling mortar | Mailose MP400 |

Jinan maissen new material co.,ltd is one of the leading cellulose ether and redispersible polymer powder producer in China.

Main products include:

HPMC-hydroxypropyl methyl cellulose

HEMC-Hydroxyethyl methyl cellulose

RDP-Redispersible polymer powder

For more information about our products, welcome to contact with us directly.